- Products

- Use Cases

- Process contractors and validate credentials

- Improve facility compliance to industry standards

- Improve speed of visitor check-in process

- Screen visitors or restrict access to my facility

- Automate my reception experience

- Improve and automate my facility evacuation process

- Manage facility security across multiple locations

- Industries

- Pricing

- Resources

- Company

Why You Need to Automate Your Workplace Emergency Drills

April 24, 2023

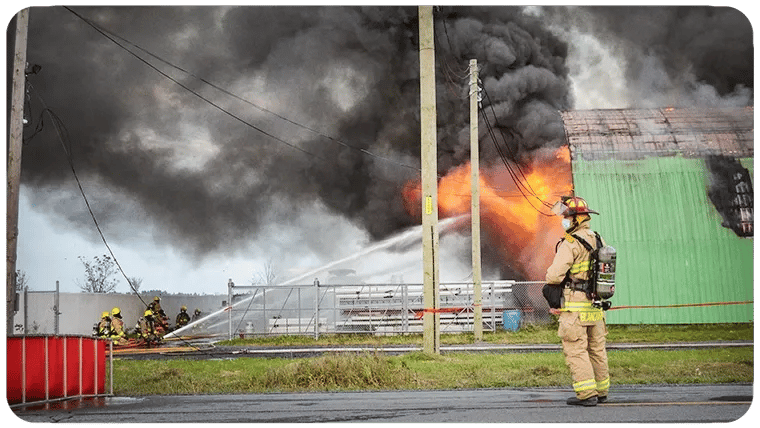

Most organizations are well aware that a real emergency could lead to serious costs. Damaged equipment and infrastructure are expensive to replace and repair – not to mention production stoppages during downtime or relocation.

What remains largely ignored is the hidden costs of running emergency drills. Every workplace has mandates to run emergency evacuation drills. Depending on the industry and regulations, drills may need to be conducted anywhere from twice a year to once a month. That doesn't even include inspections and maintenance.

How most organizations run their evacuation drills needs an update, potentially costing hundreds of thousands of dollars per site per year. Only 62% of businesses have crisis plans, and few update them or practice emergency scenarios. This lack of preparation can lead to hidden costs regarding employee safety and the company's bottom line.

Leading enterprises are employing automated workplace emergency evacuation procedures to address this issue. They offer an efficient and effective way to increase safety and reduce costs. The question is, what are these emergency costs, and why should they concern you.

This article explores the hidden costs of emergency drills and how automated evacuation procedures help increase profits while enhancing safety measures.

Biggest Unseen Costs of Running Evacuation Drills

Organizations are responsible for protecting the safety and security of their employees and visitors. Running emergency evacuation drills is one way that enterprises live up to this responsibility. However, inefficient processes and a lack of emergency planning can quickly rack up costs, with human and financial tolls. Running drills with manual, pen and paper-based processes contributes to cost and inefficiencies.

In this section, we look at some of the hidden financial costs of manual drills and how they affect your bottom line.

Inefficient Safety Procedures

Most organizations are still running drills the same way they did 100 years ago. Safety officers rely on clipboards to check on each individual, making coordination and oversight nearly impossible.

The technology to adopt emergency management best practices exists. However, the slow adoption of these tools exposes organizations to risks and hidden costs:

Slower evacuation

According to a 2023 ASIS study, the majority of organizations have internal mandates to improve evacuation speed. Despite this, only a minority are actually implementing strategies to monitor and inform improvements.

As a result, evacuation speeds remain stagnant. In a real emergency, slow evacuations mean employees may struggle to evacuate the premises promptly, increasing the potential for injury or loss of life. For drills, this lack of improvement and data can lead to audits and compliance issues, leading to costly fines and penalties.

Increased legal liabilities

Businesses that do not adhere to proper safety procedures may face legal ramifications, which can result in costly lawsuits, penalties, and damages.

Higher insurance premiums

Insurance companies may evaluate a business's risk level based on the effectiveness of its emergency preparedness. Inefficient safety procedures can lead to higher insurance premiums, thus increasing operational costs.

Lost productivity

Lost productivity is the highest cost of inefficient evacuation processes. The longer a drill takes, the more downtime and less production time. In 8 Signs You Need to Digitize Emergency Management, we reveal that unplanned downtime can cost as much as $20,000 per minute due to lost productivity.

A faster evacuation process, with reliable, efficient digitized mustering, helps get everyone out and complete headcounts quickly to return to work faster.

In addition to a slow return after evacuation, lost productivity can also occur due to staff injuries, property damage, and psychological trauma. Minimize this loss of productivity by implementing efficient and automated workplace emergency evacuation procedures.

Unclear or Lacking Communication Processes and Capabilities

Clear and effective communications are the core of safe, successful emergency procedures. When businesses do not effectively communicate their emergency plans, they may face several consequences that affect their bottom line:

Increased confusion

Unclear communications cause misunderstandings among employees about their roles and responsibilities during an emergency. This confusion can result in disorganized evacuations, slower response times, and a higher likelihood of accidents and injuries.

Facilities that rely on alarms alone leave room for confused or missed communications. Technology that enables mass notification and two-way communication using SMS enhances emergency communication capabilities. More details can be provided, as well as updates and evacuation routes. Offsite employees and visitors can even indicate that they are safe, completing roll call remotely.

Lower employee confidence

When employees are not well-informed about safety procedures, it diminishes their confidence in handling emergencies. Lack of confidence negatively affects employee morale and overall workplace satisfaction, which can harm productivity.

Increased turnover rates

Replacing employees is time-consuming and expensive, costing from 16% to 213% of the employee’s salary. It’s well worth taking steps to improve retention.

Employees who feel unsafe in their work environment may choose to seek employment elsewhere. Increased turnover leads to higher recruitment and training costs. It can also mean slower production while new employees learn the ropes.

How to use Emergency Drill Automation to Increase Profits

This section delves into how businesses can utilize workplace automation to enhance safety measures and increase profits. Discover how innovative solutions streamline emergency preparedness, reduce risks, and ultimately contribute to a more efficient and secure work environment.

Reduce Employee Downtime During and After All Types of Emergency Drills

Conducting emergency drills for the workplace is an essential part of any safety program. However, it often results in significant downtime for employees who participate. With workplace automation, businesses can minimize this downtime.

One way automation can reduce employee downtime is by streamlining training and drills. Automated training sessions can be efficient and targeted, reducing the time spent in preparation and execution. Visitors can even be given safety and evacuation videos and quizzes as part of their sign-in, using digital visitor kiosks.

Automation improves the ability to provide real-time communication and updates. Automated communication systems, such as mass notification tools, can disseminate critical information. Employees who are aware of the situation and their responsibilities can respond more efficiently and resume their work sooner.

Furthermore, automated systems track employee evacuation times, checking whether everyone has completed the drill and is accounted for. This reduces the need for manual tracking and follow-up, saving time and money.

Ensure the Safety Status of Employees and Visitors with Immediate Communication

In an emergency, immediate communication is critical. Automated messaging systems quickly alert employees of an emergency. This allows them to take necessary actions to ensure maximum safety. For instance, if there is a fire, automated systems can send messages to employees with instructions on how to evacuate the building and where to assemble outside.

This type of automation improves employee safety and saves the business money by reducing the risk of injury or loss of life. In addition to the human cost, injuries and loss of life often result in costly lawsuits and reputation damage.

Receive Real-Time Updates So All Employees Know Exactly When the Drill Ends

After the drill, employees should know when it's over. Emergency communication systems send out real-time updates to all employees, informing them that they can return to work. This reduces confusion and decreases lost work time.

Automated messaging systems provide real-time updates to employees regarding the status of the drill. Once the drill is over, the messaging system instantly notifies everyone involved that the drill is over.

Moreover, automated messaging systems can provide additional information to employees. For instance, managers can send follow-up actions for employees to take or request feedback from them.

Optimize Your Emergency Procedures for Your Emergency Drills

Optimizing emergency procedures for your emergency drills is crucial. Incorporating workplace automation can increase profits and safety by streamlining the drill process and allowing immediate communication with employees. With the right tools and procedures, you can minimize downtime, reduce confusion, and keep your employees safe in an emergency.

Learn more about optimizing your emergency procedures with iLobby's EmergencyOS, emergency management solution. This platform can help you create and manage emergency procedures and evacuation plans so you're always prepared for the unexpected. Take the first step toward a safer workplace today.

Related Posts

View All Posts

Emergency Management

6 min read

Effective Emergency Planning: A Five-Step Guide to Ensuring Safety & Compliance

Continue Reading

Guide

13 min read

The Complete Enterprise Emergency Management Guide

Continue Reading

Emergency Management

5 min read